Services

Vessel Repairs and Services:

Commercial and Industrial Diving Services

At the moment we are serving Underwater Inspection and repair under authorization of classification societies, including but not limited to:

•In water inspection of vessels, Mobile and fixed offshore structures and temporary repair such as sea chest blanking

•In- water NDT, Seam weld Inspection

•Pintle, bearing clearance and wall thickness measurement of vessels

•Propeller, sea chest inspection, Measurement and Partial Underwater Repair

•Underwater installation such as Anode, spool

•In –water Coating application

•Other Topside integrated services

•Hull cleaning & propeller polishing to improve cruise speed and fuel consumption

•Zinc Anodes replacement on vessel and MODU in water and on height by Rope Access Method

Carrying out and applying slurry blast coating and paint on offshore platforms of drilling rigs and tankers in service

By combining water with abrasives, this device produces up to 90% less dust and saves up to 80% in the consumption of grit or mesbar, in addition, having a certificate (ATEX) can be active in the conditions (No shot down required) Oil and gas rigs and refineries can be used without the risk of explosion.

Also, because the water becomes powder with the grout, the amount of water remaining is very small and easily dried by the air pressure of the device.

:Slurry blast

Benefits of Slurry Blast and modern device used

When the abrasive is mixed with water in the tank of the device, a slurry (wet abrasive) is formed which under air pressure (compressor) performs surface preparation operations more effectively than the sandblasting method.

Due to the various parameters of the modern slurry blasting machine, Wet Abrasive Blasting operation is much more controllable than other surface preparation methods and has various advantages.

1. The device has ATEX (Explosion Proof) standard and is suitable for working on oil and gas platforms while working or the deck of tankers.

2. Removal of dust from the workshop environment compared to sand blasting: which makes it suitable for working on oil and gas platforms and there is no need to remove F&G systems and other systems from the circuit.

3. Compared to other methods such as hydroblasts, it consumes very little water and in fact we only have a wet surface.

4. Surface preparation is done at a higher speed.

5. It has a higher surface quality and also has the same surface roughness as other surface preparation methods.

It is significantly less than the slurry operation, and this speeds up the whole job.

7. Enables the use of corrosion inhibitors (inhibitors) during work and allows staining to be done up to about 48 hours after wet blasting operation and does not require re-blasting.

8. According to NACE standard: WAD / 2 / SSPC, WET Blast method is used for low level of salt on the surface.

:Deck slurry blast and Anode installation

:Vessel Repairing

Seavansea Job Maritime Repair Services consists a group of professionals with extensive experience in various fields of the Maritime Industry, all with a common interest, to provide ship owners and managers a single unsurpassed reliable and professional vessel maintenance and repair services.

At the moment we are serving below services including but not limited to:

*Supply of required marine engine parts and machinery

*Repairing the shaft, propeller , rudder and shuttle, and vessels propeller angle repairs

*Piping and plating on board vessel & in machinery room and in engine roo ، in water sea chest blanking and valve replacing

Shaft and impeller repairs, overboard piping and engine room

Inspection, Repair and Maintenance of drilling rigs (IRM):

Under-class inspection, non-destructive underwater inspection, surface and underwater overhaul and maintenance

1. Performing underwater repair services including non-destructive underwater testing (MPI), moss cutting and inspection on MAP DRILLER ONE drilling rig of Mapna Company

2. Carrying out repair and maintenance services, including replacing the anodes at height on the bases by rope access method, inside the spade and under water, and on the drilling rig spade with the use of underwater welding and reviving the cover by slerry blast method and applying paint on the tanks and deck of the drilling rig. , High quality heli deck and performing touch-ups on most equipment, handrails, channels, pipes, etc., paint in different parts on SAHAR II drilling rig, North Drilling Company

3. Perform underwater washing operations and remove the ship anchor using sono scan and air lift

4. Installation of anodes and reinforcing members by underwater welding on Qeshm wharf

5. Repairs of oil tanker super tanker including pipeline repairs, deck slurry and painting

6. Repairs of Splash areas of South Pars SPD5 platform, including welding and blasting above and under water and applying paste coating under water

Subsea construction and installation

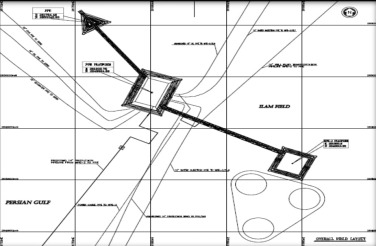

Oil and gas projects have been targeted by Seavansea as a diversification plan. Thanks to of founders’ experience of this company in this field, Sevansea has been equipped and developed in this section vastly.

Engineering, Construction or fabrication of subsea items and installation and commissioning of these items have been carried out by this company.

To this end, Seavansea deployed the best subcontractors and fleets in region to deliver best quality services to clients.

Oil and gas projects:

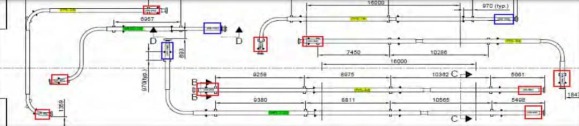

Contracting offshore projects and performing piping and spooling on the seabed

Industrial diving:

Saturated diving and mixing for underwater repairs and underwater and non-destructive inspections.

Supply and rental of materials and equipment:

Supply and all equipment required for vessels and platforms for periodic repairs.

vessel chartering:

Marine operation department in seavansea, actives in chartering of all type of vessels .Considering vast relationship with international vessel owners, this company is a role player in this market. An essential feature of this section is special purpose vessels offering.

Catering Services:

Seavnsea due to the nature of services, have been requested for material logistic by its employees frequently; In Consequence to response to this demand, Logistic department of this company started its activity and ended to Catering services that in addition to material logistic covers the hoteling services.

To satisfy non Iranian clients in this objective, seavansea benefits (enjoys) from foreign companies who are active in this field in region. Competitiveness is cornerstone of Seavansea in this field of operation with consideration of local competitors. This point has been proved in several tenders.

Offshore facilities

EPC & EPCI Capability

During the past decade EPC projects have become increasingly important and have allowed Seavansea to specialize in these disciplines, whereby field and shop engineering are also part of its offering. This puts Seavansea in an ideal position for very early involvement in asset development, being able to provide drawings with full costing and schedule for the purpose of internal review and approval by its customers in a short time frame.

Project Management

The flat organization of Seavansea is characterized by open and short communication lines. Highly skilled and experienced project management staff is a major company asset. Long term relationships with experts, suppliers and subcontractors allows Seavansea to maintain firm control on safety, quality, planning and costs. A fully integrated project team, consisting of the Seavansea project management team and its major subcontractors, will be permanently based on Seavansea premises throughout the project execution phase to allows close progress and cost monitoring and management and comprehensive reporting.

Procurement and Subcontracting

Procurement and subcontracting is done in close cooperation with the engineering and contractual departments and fully covers the provision of requisitions, data sheets and technical review. External auditing and expediting will ensure timely and flawless delivery.

Construction – Assembly – Pre-commissioning

Wide range of construction and assembly equipment in combination with highly qualified and experienced construction staff are prerequisites for the highest quality and on time delivery. Seavansea provides a wide range multi discipline services comprising steel assemblies, instrumentation, electrical, piping and mechanical installations in construction yards to complete jackets, decks, accommodation modules and modular platforms.

Heavy lifting equipment, testing equipment and pre-commissioning plans are further keys features that enables Seavansea to complete the maximum level of pre-commissioning prior to hook up and commissioning.

Hook-up and Commissioning

Prior to final handover to the client, Seavansea will undertake full offshore hook-up and final commissioning, being supported by its subcontractors and Seavansea staff. For client convenience, the provision of temporary accommodation, construction support and offshore transportation can be arranged as well.