Vessel Repairs and Services:

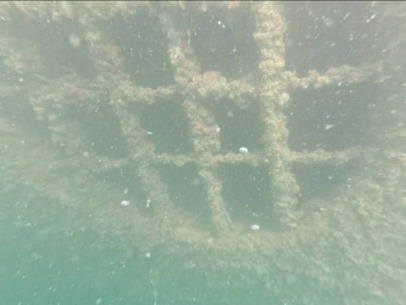

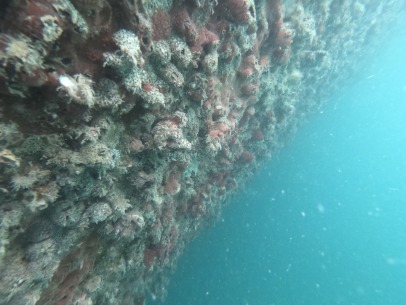

1-Under water inspection, repair and Hull cleaning of more than 43 VLCC vessel for NITC

2-Under water inspection, repair and Hull cleaning of more than 61 CONTAINER vessels for IRISL3-Hull cleaning of more than 37 vessels for different owners.

4-Under water inspection under IACS class of more than 3 MODUs

5-Partial Repair and plating, Anode replacement, under water NDT (MPI) & inspection of Map Driller One Jack up Rig-2017 for Mapna Oil and Gas Co.

6-In-Water Installation of long diagonal Brace and welding in 20 m water depth for Konarak water treatment jetty

7-Cutting of 10 the old piles at seabed for clearance for Qeshm free zone jetty

8-Cutting the corroded Anode and Installation & Welding of the new one for Rajaee port Jetty

9-Repair and maintenance of the SAHAR II MODU including the Anodes replacement on Height By Rope access Method, in water by underwater wet welding method and coating repair on Mud pit tank,Helly deck and Main deck by Wet Blasting Method

Vessel repairing:

1-Supply of marine engine parts of 2 CONTAINER vessels for IRISL

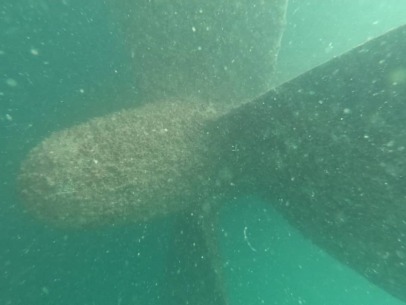

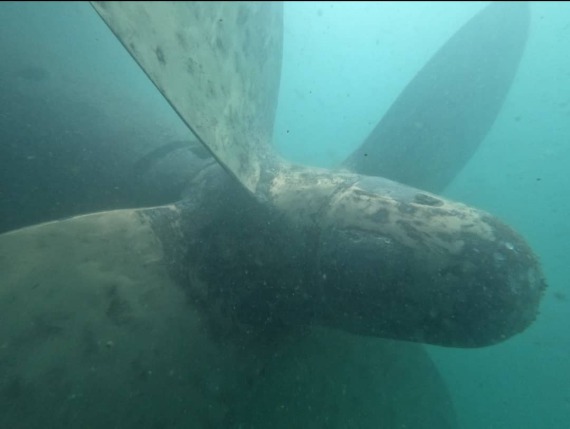

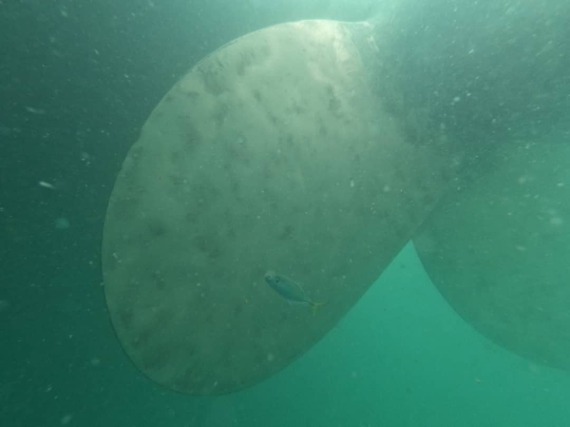

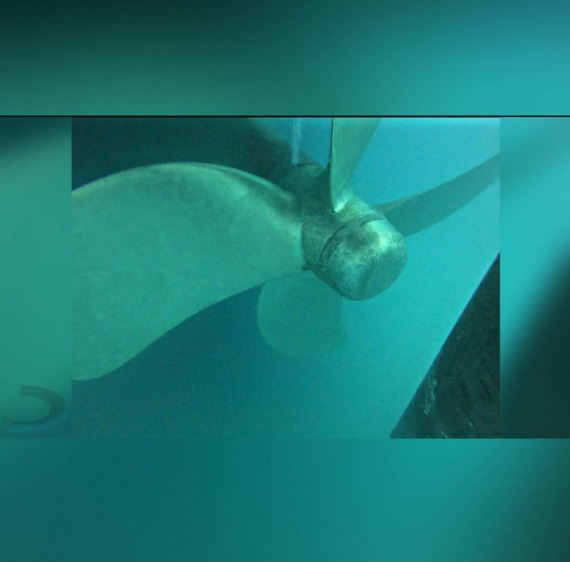

2-Repairing the shaft, propeller, rudder of 1 vessel for different owner

3-Shaft & Pintle clearance Measurement on more than 30 VLCC & CONTAINER vessels for IRISL and NITC

Inspection, repair and maintenance of drilling rigs and rigs (IRM):

1. Repairs of oil tanker super tanker including pipeline repairs, slack blast and deck painting

2. Carrying out repair and maintenance services, including replacing the anodes at height on the bases by means of rope access, inside the spade and under water, and on the spade drill of the drilling rig, using underwater welding and reviving the cover and performing slurry blasting and painting in the tanks and deck of the drilling rig. Sahar II

3. Carrying out repair services, including installation of moss anode and inspection on more than 43 super tankers of the oil company

4. Carrying out moss repair and inspection services on more than 61 container vessels on the Shipping Company of the Islamic Republic of Iran

5- Performing inspection under the cutting class of Map Driller one and SAHAR I drilling rigs

6- Performing repairs of Devon floating deck cover by Asli Blast method

7- Repairs of SPD14 platform well valve cover by slurry Blast method

Oil and gas projects:

Carrying out of Metrology for spool installation at Ilam Field (at - 65 m water depth and Mix gas diving method)

2-Engineering, Fabrication, Transportation, installation and commissioning of Ilam pipeline Spools (at - 65 m water depth and Saturation Diving Method)

3-Leakage identification on Ilam pipeline (at - 65 m water depth and Mix gas diving method)

4-Leakage removal on Ilam Pipeline (at - 65 m water depth and Mix gas diving method)

5-Utilization of Mermaid Endurer DPII Diving Support Vessel including saturation diving method for performing of Installation the 14" spools projects.

6-Utilization of ROV for different inspection and monitoring of operation

Industrial diving:

1- Performing underwater repair services including non-destructive underwater tests (MPI)

2- Repairs of Splash areas of South Pars SPD5 platform, including welding and blasting

3- Elimination of leakage of Ilam oil pipeline at a depth of 65 meters with mixed diving system

4- Installation and pressure test on 14-inch pipelines of Ilam oil region with saturated diving system and DPII diving float at a depth of 65 meters

Supply and rental of materials and equipment:

1- Supply of items and engine parts, including gas pump pump, heat exchanger, etc.

2- Supplying valve flange piping items in different classes

3- Supplying items and consumable materials for paints and sacrificial anodes for drilling rigs

Equipment section in the gallery